HLM-102

This specification describes the positive electrode material of the 102-type lithium-ion battery produced by Hunan Haili Lithium Technology Co., Ltd. (hereinafter referred to as Haili Lithium), with the molecular formula LiMn2O4.

classification:

Lithium battery

keyword:

haili

annex:

Contact Us

DESCRIPTION

1 Introduction

This specification describes the positive electrode material of the 102-type lithium-ion battery produced by Hunan Haili Lithium Technology Co., Ltd. (hereinafter referred to as Haili Lithium), with the molecular formula LiMn2O4.

2. Model: HLM-102

3. Scope of application of the product

It is suitable for grid energy storage, small household energy storage, electric vehicles, urban logistics vehicles, electric bicycles and other fields.

4. Product Features

This product uses a special doping method to improve the stability of the material lattice, superior material processing performance, good flexibility of the pole piece, good compatibility with conventional electrolytes, has the advantages of taking into account the first discharge capacity and cycle life, and has good high and low temperature performance .

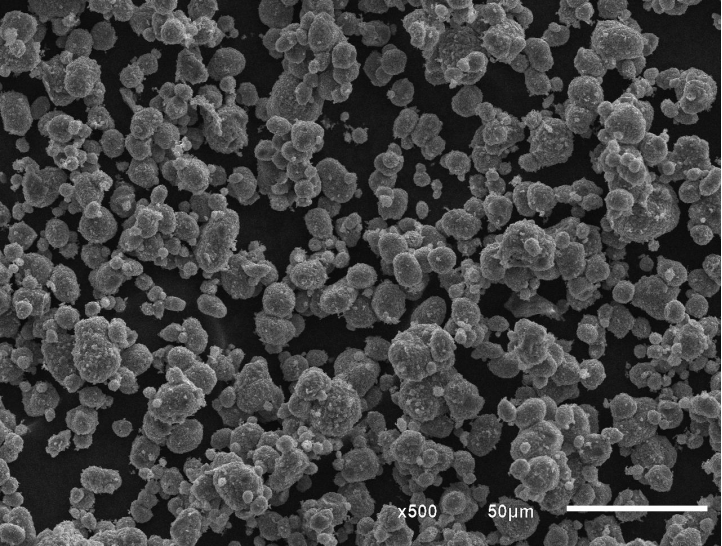

(1) The product particles are complete and regular spinel phase, the particle size distribution is normal distribution, and the material processing performance is superior.

(2) The product has excellent electrochemical performance. The normal temperature 1C gram capacity is greater than 115mAh/g, the cycle is 600 cycles, and the capacity retention rate is greater than 80%.

(3) The product has superior high-temperature cycle performance. 45°C high temperature cycle for 500 cycles, the capacity retention rate is greater than 80%.

(4) There is no impurity phase in X-ray diffraction of the product.

5. Physical indicators

5.1. Physical and chemical indicators

|

product name |

Lithium manganese oxide |

model |

HLM-102 |

|||

|

Chemical Composition and Physical Indicators |

||||||

|

Analysis Project |

standard value |

typical value |

testing method |

|||

|

Mn,% |

≥57.0 |

58.62 |

volumetric method |

|||

|

Li,% |

4.2±0.2 |

4.18 |

AAS |

|||

|

K,% |

≤0.03 |

0.0010 |

AAS |

|||

|

Na,% |

≤0.10 |

0.013 |

AAS |

|||

|

Fe,% |

≤0.01 |

0.003 |

AAS |

|||

|

Ca,% |

≤0.12 |

0.010 |

AAS |

|||

|

Cu,% |

≤0.01 |

0.0001 |

AAS |

|||

|

SO42-,% |

≤1.2 |

0.06 |

gravimetric method |

|||

|

H 2 O, % |

≤0.08 |

0.04 |

Karl Fischer method |

|||

|

Specific surface, m 2 /g |

≤0.8 |

0.51 |

Specific surface tester |

|||

|

Magnetic substance, ppb |

≤1500 |

426 |

ICP |

|||

|

Tap density, g/ cm3 |

≥1.8 |

2.12 |

Tap Density Meter |

|||

|

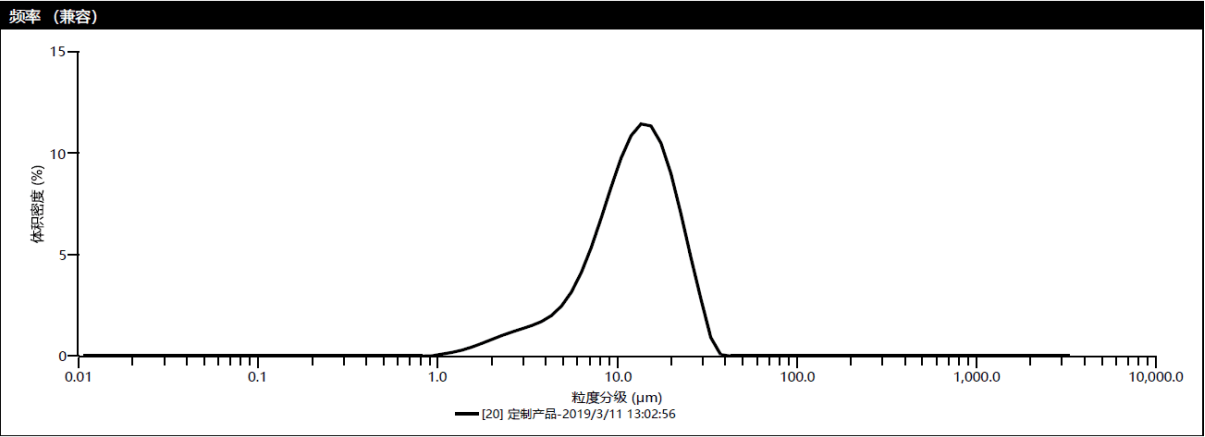

Granularity (um) (can be adjusted according to customer requirements) |

D 10 |

≥4.0 |

6.43 |

Malvern particle size analyzer |

||

|

D50 |

10~16 |

14.0 |

||||

|

D 90 |

≤30 |

25.6 |

||||

5.2. Basic electrical performance indicators

|

project |

standard value |

typical value |

testing method |

|

Compacted density (g/cm 3 ) |

≥2.65 |

2.70 |

Reference data provided by downstream customers |

|

Button power 1C discharge specific capacity (mAh/g) |

≥115 |

118 |

Blue Electric Battery Tester |

|

600-cycle cycle capacity retention at room temperature (1C charge and discharge) |

≥80 |

82 |

Blue Electric Battery Tester |

|

45°C 500-cycle cycle capacity retention (1C charge and discharge) |

≥80 |

81 |

Blue Electric Battery Tester |

5.3. Particle size distribution

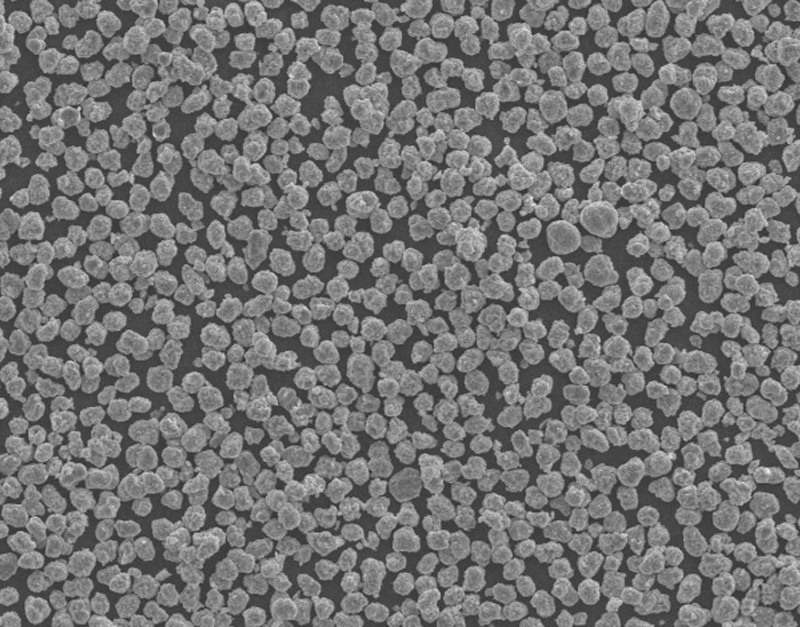

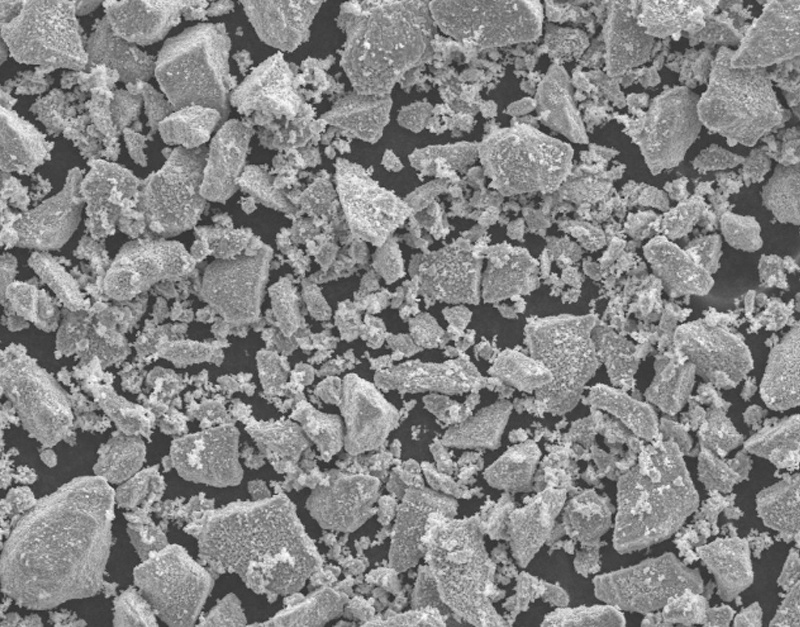

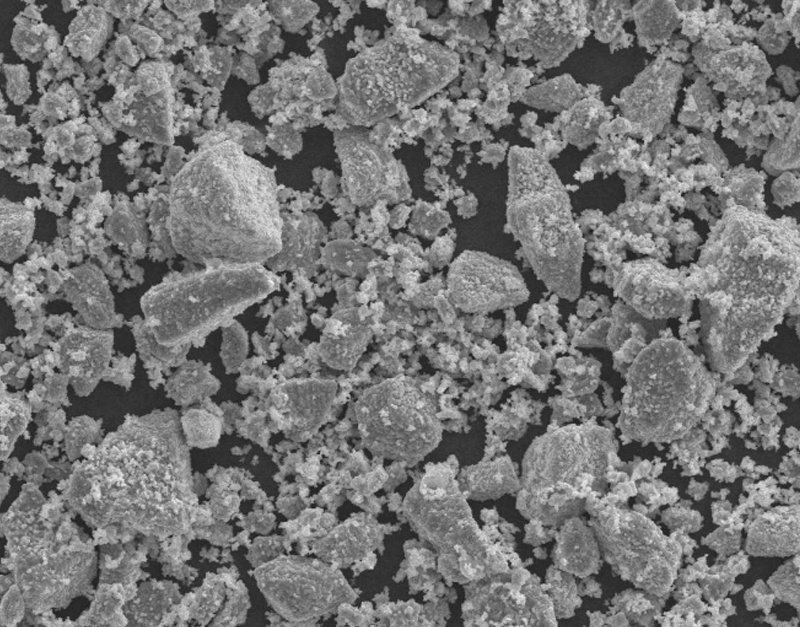

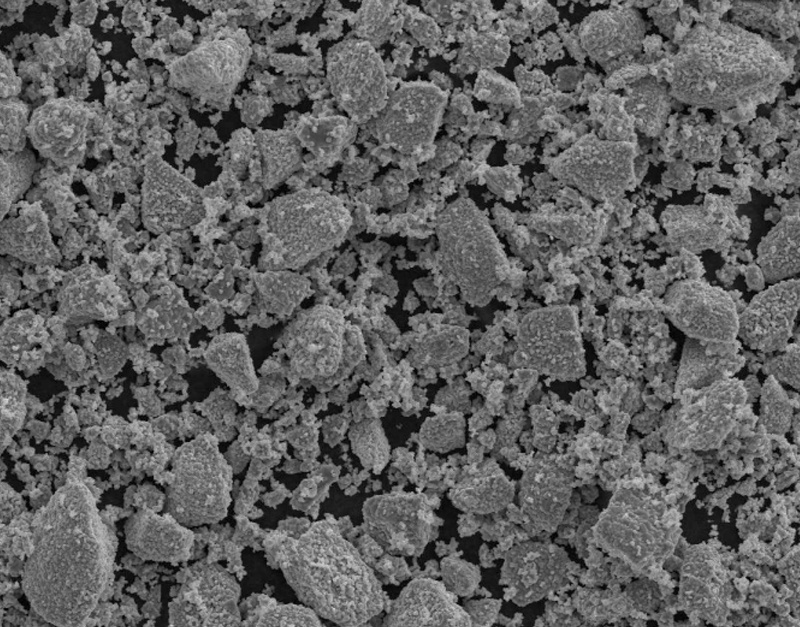

5.4 Electron microscope image

6. Packaging and storage conditions

6.1. Packing method: Inner aluminum foil bag, vacuum packaging, outer carton, 25kg/box.

6.2. Requirements for stacking layers: carton packaging ≤ 3 layers.

6.3. Label style: the default Haili lithium battery shipping label, if the customer has special requirements, it can be implemented according to the label style provided by the customer.

6.4. Storage conditions: Keep sealed and avoid direct sunlight. The recommended storage temperature is ≤37°C and the humidity is ≤50%RH. The shelf life is 1 year. If the product exceeds the shelf life, it should be inspected by our company and re-evaluated whether it can be used normally.

6.5. Under the condition of unsealing, strictly control the storage humidity to ≤30%RH, and use it as soon as possible.

7. Precautions for transportation

When loading, do not place heavy objects on top of the cartons to prevent deformation of the cartons; prevent extrusion and sun and rain; use vehicles, trains, ships, planes and other vehicles for transportation.

8. Suggestions for processing and use

Positive electrode ratio: lithium manganate 95.0%~96.5%, conductive agent 1.0%~2.5%, PVDF 2.0%~3.0%. It is recommended to use PVDF with a molecular weight greater than 1 million as the binder. If the binder is made by the suspension method, the dosage can be adjusted to 1.5% to 2.0%.

Suggested negative electrode excess ratio: 8﹪~12﹪.

It is recommended to use compaction: 2.65~2.75g/cm3.

Recommended