HLY-NM

This specification describes the cobalt-free nickel-manganese binary lithium-ion battery cathode material produced by Hunan Haili Lithium Technology Co., Ltd. (hereinafter referred to as Haili Lithium).

classification:

Lithium battery

keyword:

haili

annex:

Contact Us

DESCRIPTION

1 Introduction

This specification describes the cobalt-free nickel-manganese binary lithium-ion battery cathode material produced by Hunan Haili Lithium Technology Co., Ltd. (hereinafter referred to as Haili Lithium).

2. Model: HLY-NM

3. Scope of application of the product

This product has a wide range of applications. The capacity type product can be applied to various 3C digital electronic products; the power type product can be used in low-speed vehicles, unmanned aerial vehicles and pure electric vehicles.

4. Product Features

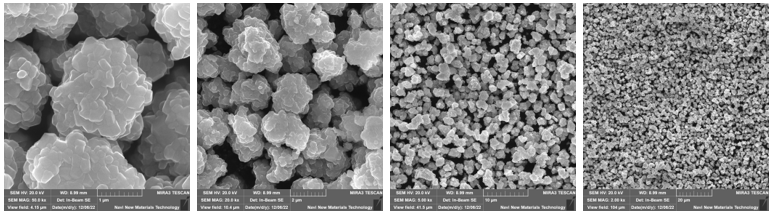

The production of this product adopts a special co-precipitation method to synthesize a small particle size nickel-manganese binary precursor, and adopts a segmented atmosphere sintering technology. The synthesized bare material has a stable structure and excellent electrochemical performance, while taking into account high specific capacity and cycle stability. , has the characteristics of high cost performance.

(1) The product particles have a complete α-NaFeO 2 layered crystal structure, the X-ray diffraction pattern has no miscellaneous peaks, the particle size is normally distributed, and the material processing performance is superior.

(2) Eliminate the path dependence of layered cathode materials on cobalt resources, and improve the strategic autonomy of raw material supply and demand.

(3) Bare material products have excellent electrochemical performance. The 1C capacity (cut-off voltage 4.3V) is greater than 170mAh/g at room temperature, and the capacity retention rate is greater than 88.8% after 100 cycles of 1C cycle. Using special precursor doping technology or unique modification methods, the capacity retention rate can be further increased to more than 90%, and the charge cut-off voltage can be increased to 4.4V, further improving the energy density of the system.

(4) The product has a wide range of uses, which can be used to prepare secondary balls and to synthesize single crystals.

(5) Through simple physical compounding with low-capacity products such as lithium manganate, on the one hand, it fills the particle gap and improves processing performance; market competitiveness, and then broaden its application space, with high cost performance.

5. Physical indicators

5.1. Physical and chemical indicators

|

product name |

binary material |

model |

HLY-NM |

|

|

Chemical Composition and Physical Indicators |

||||

|

Analysis Project |

typical value |

testing method |

||

|

Ni+Co+ Mn,% |

58~63 |

61.50 |

volumetric method |

|

|

Li,% |

7.2±0.3 |

7.03 |

AAS |

|

|

K, ppm |

≤100 |

3 |

AAS |

|

|

Na,ppm |

≤500 |

38 |

AAS |

|

|

Fe,ppm |

≤100 |

9 |

AAS |

|

|

SO42-,% |

≤0.5 |

0.12 |

gravimetric method |

|

|

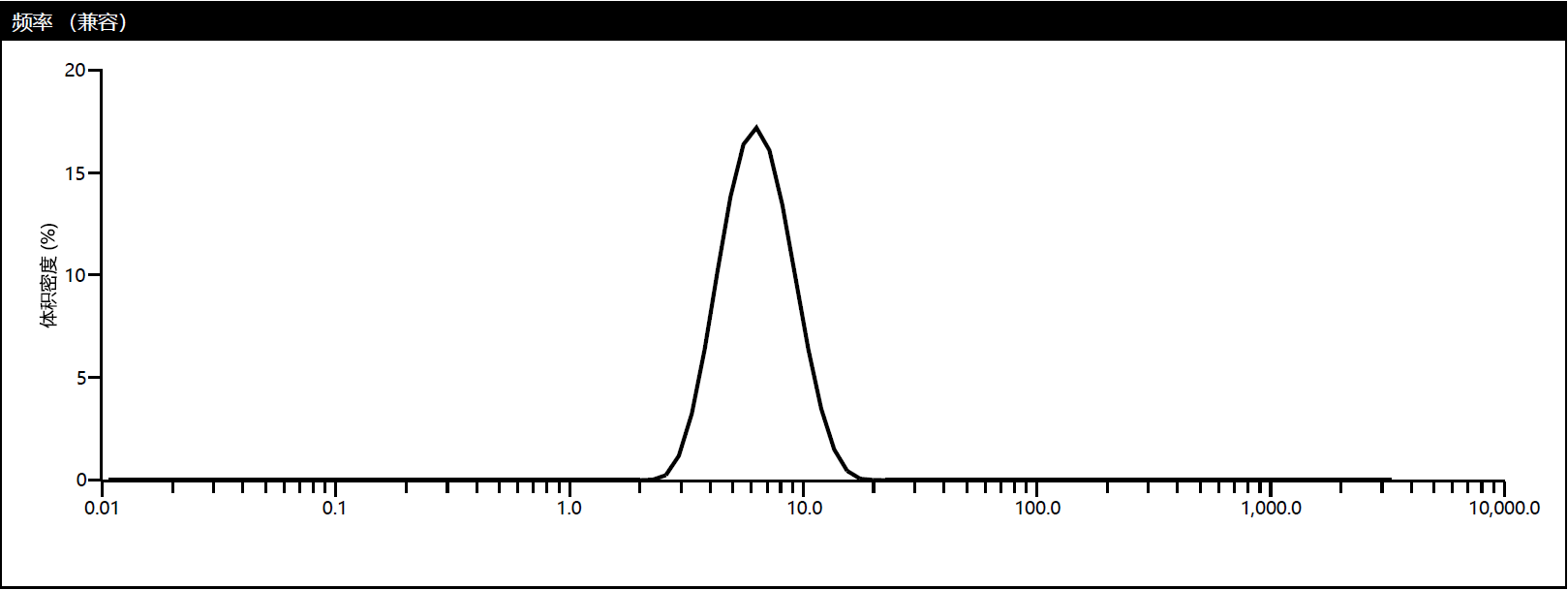

Granularity (um) (can be adjusted according to customer requirements) |

D 10 |

≥3.0 |

4.1 |

Malvern particle size analyzer |

|

D50 |

5.0~12.0 |

6.3 |

||

|

D 90 |

≤30 |

9.81 |

||

5.2 Basic electrical performance indicators

|

project |

standard value |

typical value |

testing method |

|

|

granularity (µm) |

D10 |

≥3.0 |

4.1 |

Malvern particle size analyzer |

|

D50 |

5.0~12.0 |

6.3 |

Malvern particle size analyzer |

|

|

D90 |

≤30.0 |

9.81 |

Malvern particle size analyzer |

|

|

Button power 1C discharge specific capacity (mAh/g) |

≥155 |

170 |

Blue Electric Battery Tester |

|

|

0.1C first charge and discharge efficiency (%) |

≥88% |

92 |

Blue Electric Battery Tester |

|

|

100-cycle cycle capacity retention at room temperature (1C charge/discharge/deduction) |

≥80 |

88.8 |

Blue Electric Battery Tester |

|

5.3 Particle size distribution

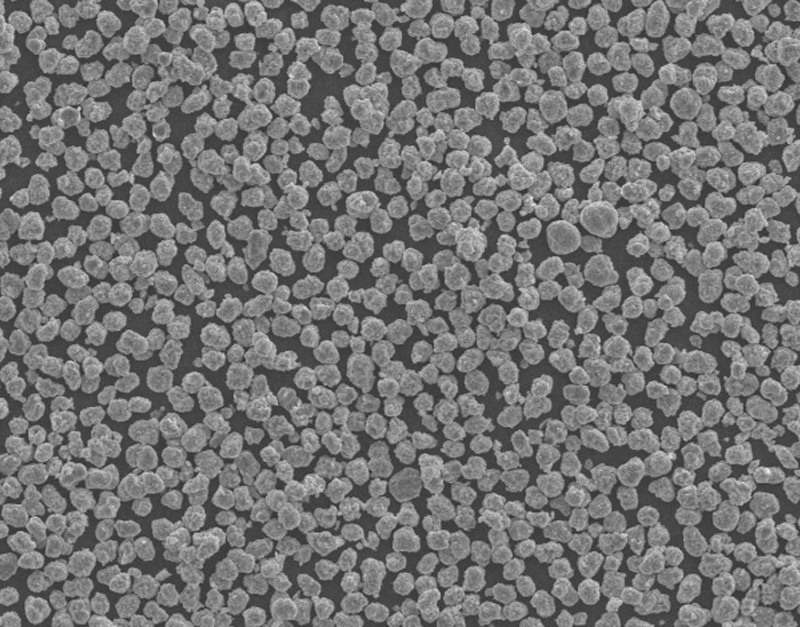

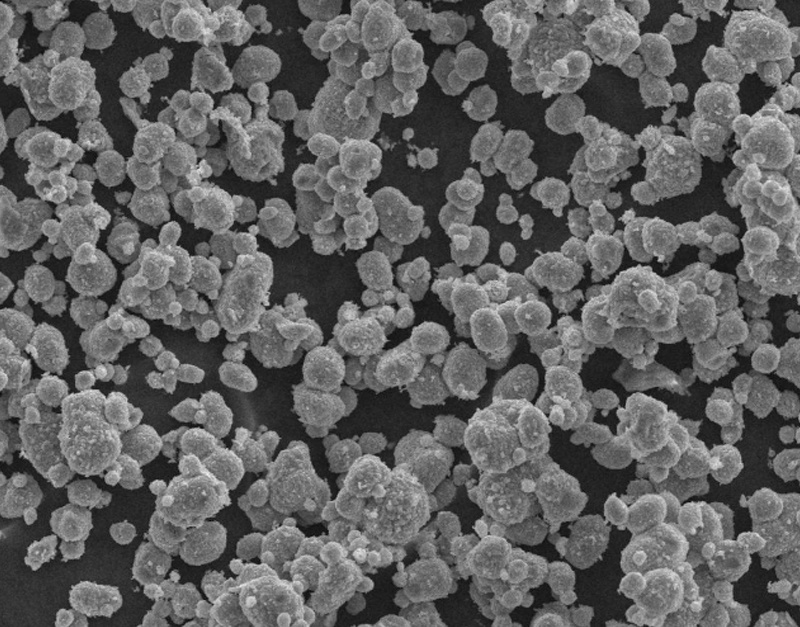

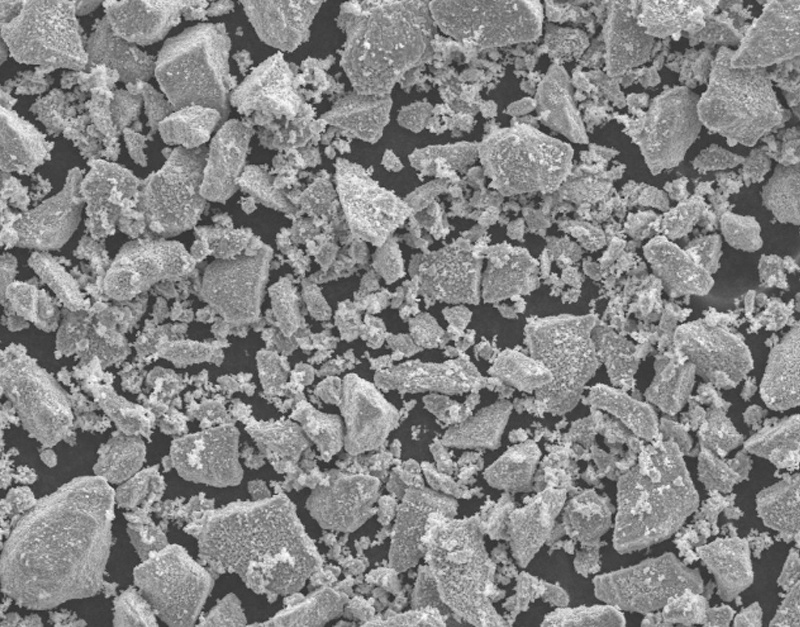

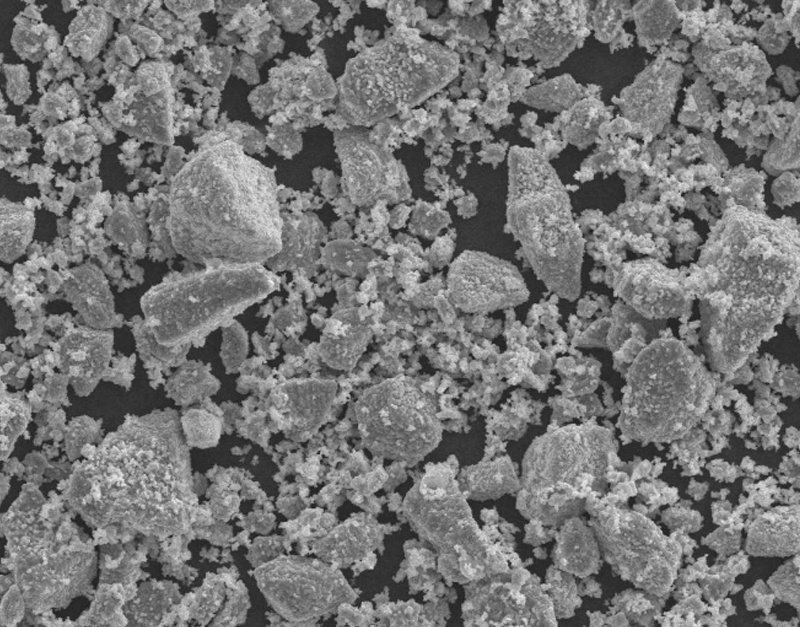

5.4 SEM image

6. Packaging and storage conditions

6.1. Packing method: Inner aluminum foil bag, vacuum packaging, outer carton, 25kg/box.

6.2. Requirements for stacking layers: carton packaging ≤ 3 layers.

6.3. Label style: the default Haili lithium battery shipping label, if the customer has special requirements, it can be implemented according to the label style provided by the customer.

6.4. Storage conditions: Keep sealed and avoid direct sunlight. The recommended storage temperature is 20±10°C and the humidity is ≤50%RH. The shelf life is 2 years. If the product exceeds the shelf life, it should be inspected by our company and re-evaluated whether it can be used normally.

6.5. Under the condition of unsealing, strictly control the storage humidity to ≤30%RH, and use it as soon as possible.

7. Precautions for transportation

When loading, do not place heavy objects on top of the carton to prevent deformation of the carton; prevent extrusion and sun and rain; can be transported by vehicles, trains, ships, planes and other means of transportation.

Recommended